Sealing expertise for CCUS applications

CCUS, essential technologies to achieve net zero

Global warming continues at a rapid pace. Despite technological innovation and global efforts to decarbonize the economy, there will continue to be many industrial processes where CO2 emissions are difficult or impossible to avoid. Therefore, solutions to technically reduce CO2 are urgently needed to achieve the Net Zero Emissions by 2050 (NZE) scenario.

Carbon Capture and Storage (CCS)

CCS involves the capture and storage of CO2 to prevent its release into the atmosphere at the point of origin. The CO2 is typically generated at large single point sources such as power plants, natural gas processing, blue hydrogen production, and other industrial facilities that use either fossil fuels or biomass as fuel. The captured CO2 is then compressed and injected into deep geological formations for permanent storage.

Carbon Capture and Utilization (CCU)

CCU involves the capture and subsequent industrial use of CO2. Because of its favorable properties, CO2 is already being used in a variety of ways, including as a solvent, in cooling processes, in the food and beverage industry, in chemical cleaning or in water treatment. The use of CCU can therefore replace fossil carbon sources used so far which broadens the industry's raw material base – a major benefit of the technology.

Many industries and governments around the world have recognized the big potential of CCUS technologies. The International Energy Agency (IEA) expects carbon capture to increase from 40 million tons of CO2 in 2021 to 1.8 Gt of CO2 in 2030 and 7.6 Gt of CO2 in 2050.

A

CO₂ capturing process

Pre-combustion

Post-combustion

Oxyfuel combustion

B

CO₂ compression

C

CO₂ transport and injection

Source of CO₂

- Power plants

- Refineries

- Natural gas processing

EagleBurgmann, trusted sealing technology partner for all stages of CCUS

As a key component, industrial seals are critical to the safe operation of systems. The rotating and static equipment used throughout the entire value chain must be able to cope with a variety of operating conditions and challenges. The sealing solution used and how it is designed affects not only the function, but also the operational performance and cost-effectiveness of the system.

This is what makes CO2 a challenge

CO2 applications can be challenging, especially for the pumping technology used. While CO2 compressors operate primarily at high temperatures and thus in non-critical thermodynamic ranges, CO2 phase changes are possible in pumps. Depending on the prevailing pressure, volume, and temperature conditions, CO2 can be gaseous, liquid, solid or in the supercritical phase.

Possible transitions between the various phases must be considered in the design of a dry gas seal. In the worst case, if the leakage rate is too high, the very high Joule-Thomson coefficient of CO2 can cause icing as it expands through the seal gap.

Mechanical seals specifically designed for the use in CO2 pumps and CO2 compressors are therefore part of our product range.

Driving innovation together

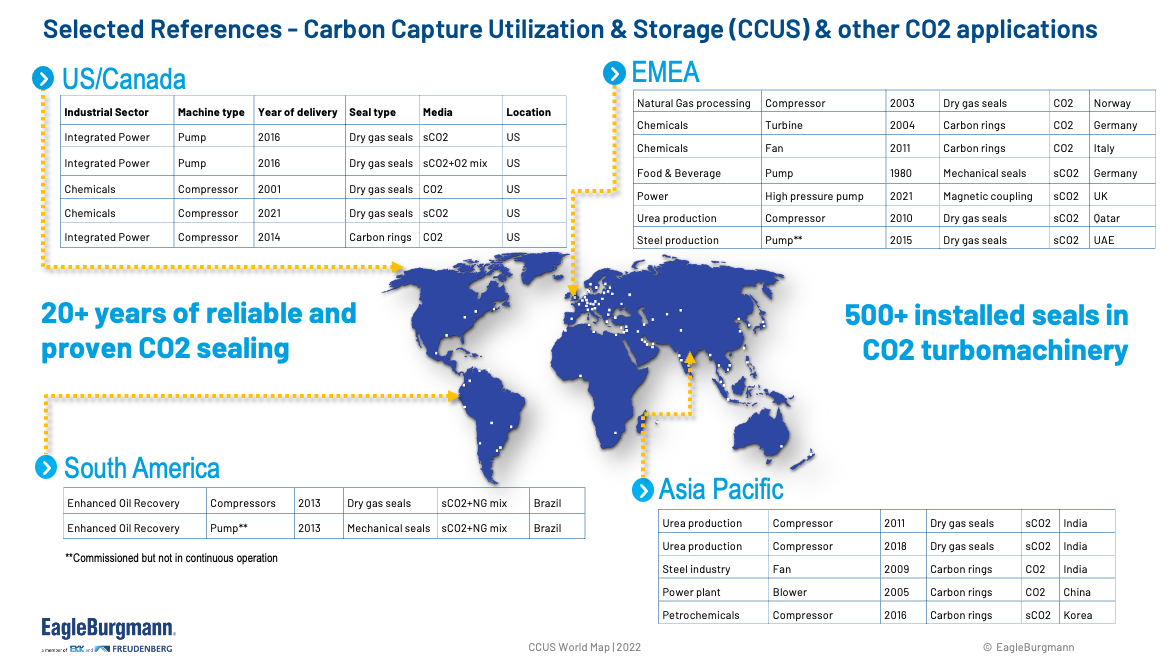

As one of the world's leading manufacturers of sealing technology, EagleBurgmann offers proven and reliable solutions for all companies looking to invest in CO2 capture, transport, storage and/or utilization. We adapt best practice standard sealing solutions to individual requirements in accordance with API Std 682 and other industry standards to minimize total life cycle costs. However, the development of new engineered sealing solutions is also possible.

You too can have access to our extensive application expertise for safe and profitable CCUS operations and sustainable economic transformation.

Key CO2-capture processes

To capture CO2 from industrial processes, three main methods are used.

Combustion of fossil fuels, such as in gas or coal-fired power plants, produces flue gases containing up to 15% CO2. With post-combustion carbon capture, approximately 89% of the CO2 can be captured before the flue gas is released into the atmosphere. Power plants require only minor technical modifications to use this now mature technology. However, the process is also being used in industrial plants, such as cement plants.

The mechanical seals used in postCCC processes must handle lean and rich solvents as well as water, across a range of temperatures. A variety of solvents may be used, such as amines, ammonia, ethers, or potassium carbonate.

Pre-combustion carbon capture removes carbon from fossil fuels before they are burned. This is done by first converting the fuel into a gaseous mixture of hydrogen and carbon dioxide. Following CO2 molecule separation, the remaining hydrogen rich mix can be used as a fuel source.

Pre-combustion processes require mechanical seals to handle similar fluids over a range of temperatures and pressures.

In the oxyfuel carbon capture process, the hydrocarbon energy source is burned in an atmosphere consisting of nearly pure oxygen instead of air. The resulting flue gas is approximately 80% CO2 and water vapor. The water vapor is then condensed out and accompanying substances such as nitrogen, oxygen, sulfur dioxide and argon are separated.

This results in a highly concentrated CO2 stream of nearly 100%, allowing for a more cost-effective capture process. However, the upstream air separation process is energy intensive.

Other technologies include the use of membranes, solid adsorbent, filters, solid loop processes, which are at various stages of technology maturity.

CO2 transport and CO2 storage

Developing a functioning CO2 infrastructure for efficient transport and safe storage will determine how widely and rapidly CCS will be deployed globally.

In principle, CO2 can be transported by ship, truck, rail, or pipeline. The use of pipelines has been proven and is now state of the art. For permanent storage, the captured CO2 is injected into deep geological formations. These include depleted oil and gas reservoirs, non-decomposable coal seams and basalts. Storage capacities at global, European, and national levels are assessed differently and are the subject of research projects.

Utilizing carbon as valuable feedstock

There are increasing efforts worldwide to utilize captured CO2 (CCU) in the sense of a circular economy. This is done either directly or as a feedstock in industrial and chemical processes to produce valuable carbon-based products.

According to the International Energy Agency (IEA), approximately 10% of captured CO2 will be used in synthetic fuels (SAF), plastics, chemicals, fertilizers or building materials. The remainder will need to be permanently stored in deep geological formations, such as depleted oil and gas reservoirs or saline aquifers.

Working together to innovate for CCUS projects of all sizes. Worldwide.

EagleBurgmann has been a reliable full-service partner to the chemical, petrochemical, liquefied petroleum gas and gas industries for many years. This allows us to follow the latest developments and, as an innovative solutions partner, be part of the journey towards the energy transition to achieve net zero together.

We support CCUS projects from the initial considerations through to the subsequent operation of the systems. OEMs, operators, and EPC companies benefit from our in-depth technical expertise, years of cross-industry experience, world-class sealing technology and comprehensive service and support.

Work with the experts

Reach out to our team and find out how we can help you with your CCUS project.

We are happy to advise you

Would you like personal advice, do you have any questions or would you like to order directly? We look forward to supporting you.

Meet our experts

The best way to meet your needs is to understand your challenges. That’s why we attend the industry’s most important events. Why don’t you stop by? We look forward to meeting you!

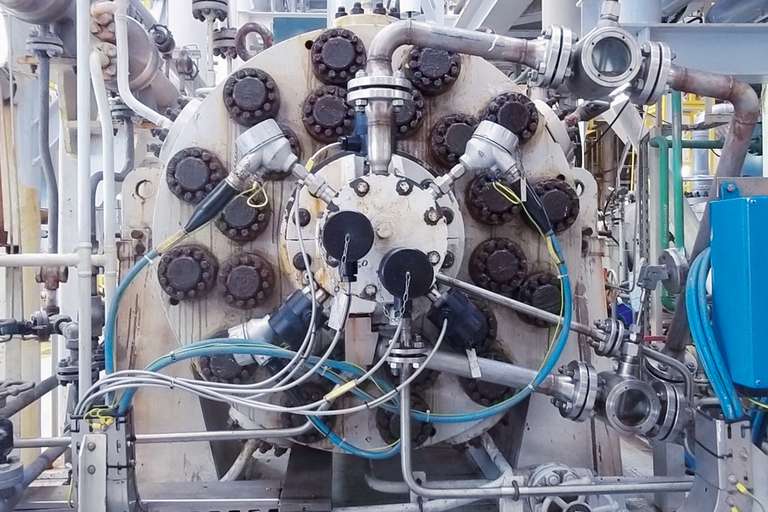

Compressor sealing solutions for industrial applications

Products. Systems. Service.

Espey WKA802 for sealing a CO2 gear compressor

Sealing solution in the fertilizer industry for a high-pressure CO2 application.

White Paper

Advanced DGS design solution for multiphase CO₂ pump applications

Optimize CO2 process and power cycle efficiencies with industry-leading sealing technology.