Situation

High-boiling toxic product is separated from the residue by evaporation in a steel distillation vessel

M481KL shaft seal for distillation units

High-boiling toxic product is separated from the residue by evaporation in a steel distillation vessel

Problematic media, and original sealing solution was not conform to current industrial standards

TA-Luft- and ATEX-compliant mechanical seal, type M481KL-D24

In the process stage presented here, a high-boiling toxic product is separated in a steel distillation vessel at Chema Prozess- und Systemtechnik (Germany) from the residue by evaporation. The distillation vessel is run discontinuously in batch operation. This means that the vessel is filled at the beginning of the process and then heated up to the operating temperature. Due to different boiling points the product is separated by distillation. When the vessel has cooled down, the residue is removed and the vessel is refilled.

The medium to be separated has a melting point of 155 °C and a tendency to resublimate, i.e. it changes its state of aggregation directly from gaseous into solid. This tendency to resublimate is problematic because product deposits can build up on the seal and can lead to the seal hanging up.

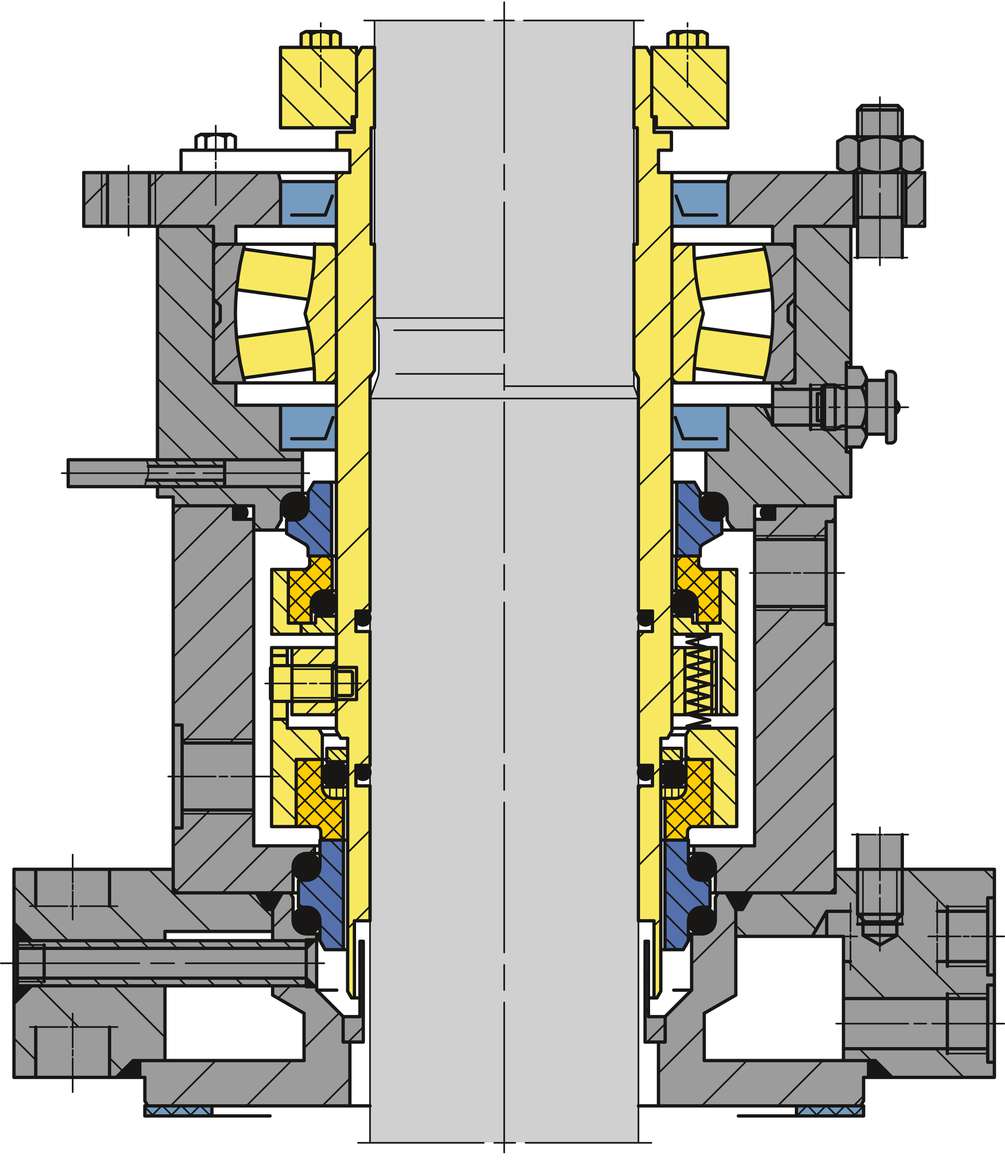

Illustr. 1: M481KL agitator seal

Illustr. 2: Yellow parts = rotating, blue = stationary, gray = housing.

Until now, the sealing was performed using a double packing with a flush. The problem with this sealing solution was that it was not conform to current industrial standards based on the today’s legislation such as TA-Luft and ATEX. In order to fulfill these requirements, the stuffing box packing was replaced by TA-Luft-compliant mechanical seal, type M481KL-D24, which is conform to ATEX Zone 1 II GD cb T3. The seal is a double mechanical seal with integrated bearing in cartridge design. The seal is self-closing.

Special features include an integrated “cooling flange” and the use of a polymerization barrier. However, in this application the “cooling”-flange is not utilized for cooling but for heating, in order to prevent product resublimation. Temperatures produced here range between 155 °C and 200 °C.

The polymerization barrier, which is a sort of labyrinth, is arranged below the seal on the product side and is continually flushed with nitrogen. This prevents the medium from reaching the seal and forming a deposit, resulting in the seal hanging up. Normally, polymerization barriers utilize liquid quench media.

Originally, it was proposed to use a medicinal grade white oil. However, the fact that this produced minor leakage into the product was unacceptable to the customer. It was therefore decided to go with nitrogen as the flush medium without retro-fitting of the seal. It is recommended to use a throttle for gaseous media in order to achieve higher flow rates. It is also possible to achieve precise drain-off of any leakage in order to fulfi ll TA-Luft air quality control requirements.

Specifically because of the high temperatures involved, a special perfluoro rubber (KH) that is resistant up to 315 °C is used for the elastomers on the product side and to some extent on the atmosphere side as well.

With this contemporary seal solution the plant operator rebuilt its equipment right up to current industrial standards and to fulfill the demands of legislation in every respect as set out by TA-Luft and ATEX. Emissions are reduced to a minimum and security of employment also achieves significant improvement. In addition, the seal’s lifetime is also noticeably prolonged.

Between June 2017 and March 2019 the Hengli Group constructed an integrated refining and chemical complex in the Chinese harbor town Dalian where 20 million tons of crude oil are processed every year. EagleBurgmann advised the company Hengli concerning the selection of mechanical seals and supply systems for the whole plant and supplied more than 95 % of the components in use.

In Great Britain, a shortage in natural gas supply has severe consequences: Since the country switched from coal-fired to gas-fired power stations, a gas supply shortage makes households and industrial consumers not only vulnerable to failing heating and gas stoves, but also to power outages. Companies along the value and transportation chain of natural gas are therefore especially dependent on reliable equipment.

Things get hot in rotary kilns, very hot in fact. In the production of cement, for example, the thermometer measures more than 1,000 degrees Celsius. Sealing systems from EagleBurgmann, a company of the Freudenberg Group and EKK, make sustainable contributions to environmental protection, energy efficiency and process reliability under these "fiery" high-temperature conditions.

Our modern civilization is quite literally built upon cement. Today, building materials made from cement are used in buildings, roads, bridges, dams etc. Cement production is a heat-intensive process and causes thermal expansion in duct systems. To compensate this, Indian cement producer Ramco Cement needed fabric expansion joints with a diameter of several meters for two of their plants. On the basis of a close collaboration, EagleBurgmann was able to design components that increase the efficiency of the plant in the long run.

Frequent starts and stops are a severe test for gas-lubricated compressor seals. Installed in an Argentinean combined cycle power plant is an EagleBurgmann supply system that provides a continuous gas flow rate for the seals and adapts it to changing conditions. Since then, the operational reliability of the compressors has increased significantly.

Seals are a risk factor in the production of liquid crystals. If there is even the slightest contamination of the liquid crystals, this will later affect the image quality of the display. Read on to see which sealing solution Merck KGaA uses in paddle dryers for the production of liquid crystals.