Situation

The OSVAT pipeline carries 55 % of the crude oil produced in Brazil. Over a distance of 275 km up to 10 different oils flow to various refineries throughout the country

Extremely wear resistant DF-HRS8 for Sulzer high pressure pipeline pumps

The OSVAT pipeline carries 55 % of the crude oil produced in Brazil. Over a distance of 275 km up to 10 different oils flow to various refineries throughout the country

Abrasive and highly viscous crude oil, and danger of partial dry running of mechanical seals due to poor lubrication and high temperatures

DF-HRS8 cartridge seals with DiamondFace coating that was applied on both sliding faces of the seals

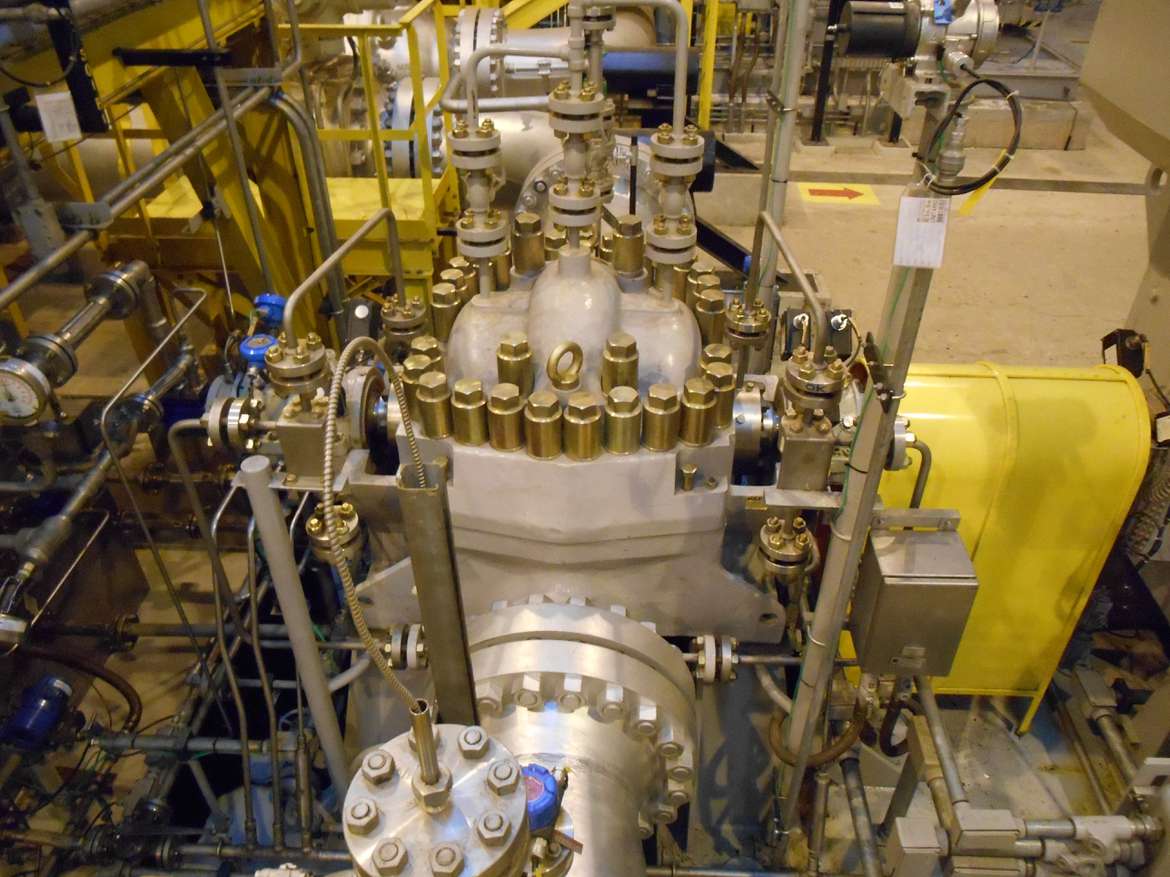

Illustr.: Sulzer heavy duty multistage centrifugal pump in operation. 12 pumps of this kind are employed at four pump stations of the Brazilian OSVAT pipeline system. The sealing system consists of two DiamondFace coated EagleBurgmann DF-HRS8 mechanical seals per pump, supplied acc. to API Plan 31.

The 275 km OSVAT pipeline network plays an indispensable role in Brazil‘s economy, carrying about 55 % of the crude oil explored in Brazil. The network supplies two Petrobras refineries in the Sao Paulo province: REPLAN (Refinaria do Planalto Paulista) in Paulinia, the company’s largest refinery (360,000 barrels/day, or about 20 % of Brazil’s current oil refining capacity), and Henrique Laga REVAP in Sao Jose dos Campos, Petrobras’ third largest refinery (250,000 barrels/day).

Up to 10 different crude oils at flow rates of about 5.5 million liters per hour are carried by the 38" (965 mm) OSVAT pipeline. The crude oils include high viscosity grades (up to 500 cSt) produced from the Bacia de Campos and Bacia de Santos fields off Brazil’s Atlantic coast. 12 Sulzer heavy duty pumps are applied to maintain the fast flow of crude oil from the wells to the final destinations.

Sulzer heavy duty multistage centrifugal pumps of types MSD and SZZM have been selected for this demanding job. The pumps were custom-engineered to match the hydraulic fit and mechanical requirements of the end user.

The Sulzer MSD pump is an axially split casing design with a double volute construction in a between-bearing arrangement, also known as an API-610 BB3 pump. The mechanical seal chambers, one at the drive end and the other at the non drive end, are equally pressurized due to throttle bushings and the integral balance line. The Sulzer SZZM is also an axially split design with just two stages in a between-bearing arrangement, also known as an API 610 BB1 type. The two stages are arranged back-to-back in order to reduce the axial load on the bearings. The same sealing concept was selected for both pump types.

The seals face a harsh environment in this specific application: an abrasive and highly viscous medium pumped at high speed. Conventional hard/hard seal faces have only limited capabilities to handle high viscosity, poor lubrication and the resulting high temperatures. The seals are subject to periodic dry running, which can degrade or even destroy the sliding faces and secondary seals. The service life of mechanical seals with conventional seal face materials is typically only a few months.

Illustr. 1: Top view of a mounted EagleBurgmann HRS8 shaft seal.

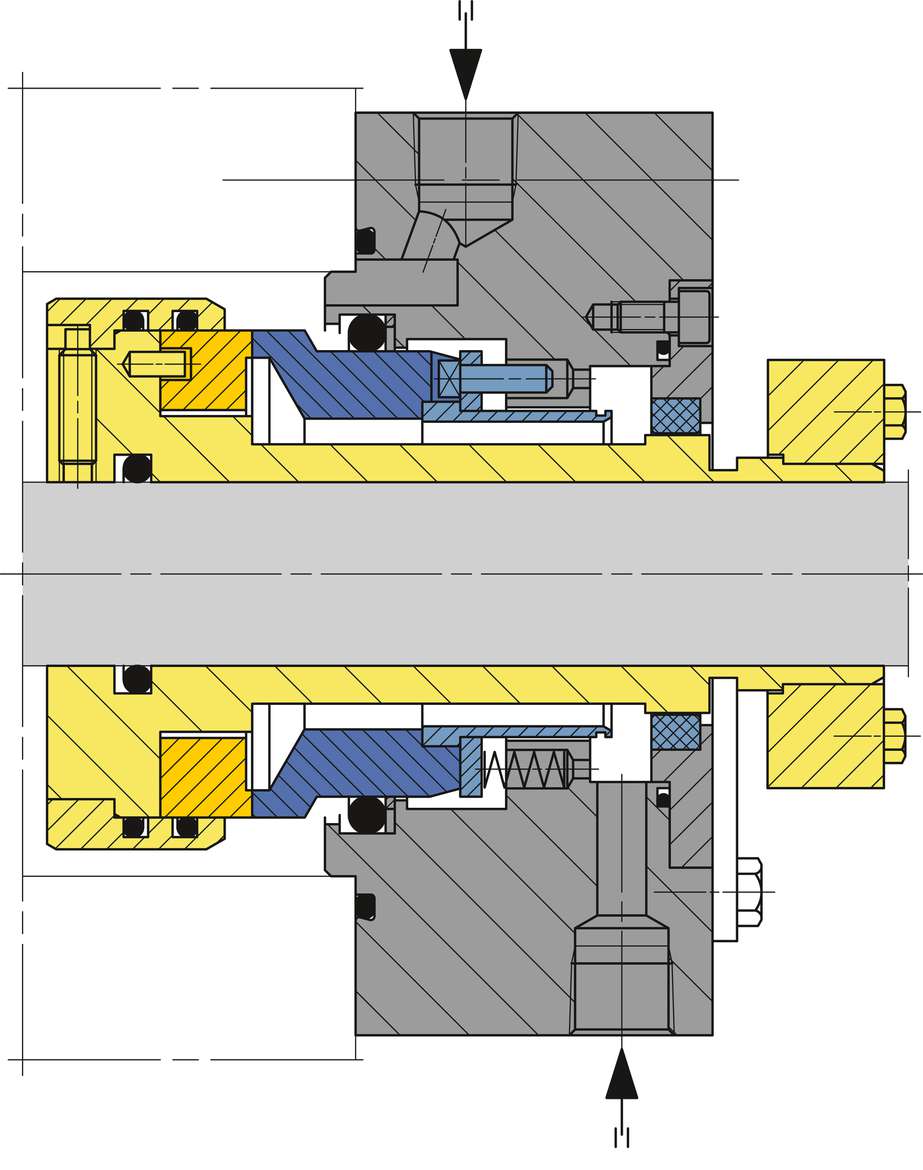

Illustr. 2: EagleBurgmann HRS8 cartridge seal. Both stationary and rotating seal faces are diamond coated. Yellow colored seal parts = rotating, blue = stationary, gray parts = housing.

To reliably seal the pumps shafts, single DF-HRS cartridge seals were applied. The seal type EagleBurgmann HRS is a well-proven design for slurry applications. Only minor modifications needed to be made in order to handle crude oil with high viscosity. Other favorable seal features are stationary seal design and multiple springs protected from the product.

Seal face lubrication and cooling is provided by flushing acc. to API Plan 31: Crude oil flows through a cyclone separator from the discharge of the pump. The clean fluid is routed to the seal chamber while the fluid with the heavier solids is routed back to the pump suction.

To avoid any seal problems with this demanding application and to significantly extend the MTBF, DiamondFace coating was applied on both sliding faces of the seals.

The crystalline diamond layer is characterized by extreme hardness, wear resistance, excellent thermal conductivity, highest chemical resistance and lowest friction coefficient, combined with maximum adhesive strength on the base material. This innovative technology turned out to be an excellent and reliable solution for applications in the oil and gas industry. Numerous references for variously demanding applications all over the world show a service life that has been greatly prolonged up to a factor of 25.

Since the start-up in 2012, OSVAT Sulzer pumps have been running without failures, and the DiamondFace coated EagleBurgmann DF-HRS8 mechanical seals have exhibited no wear so far. This results in a signifi cant economic and environmental benefi t for the operator, Petróleo Brasileiro SA (Petrobras).

Download the solution flyer

Between June 2017 and March 2019 the Hengli Group constructed an integrated refining and chemical complex in the Chinese harbor town Dalian where 20 million tons of crude oil are processed every year. EagleBurgmann advised the company Hengli concerning the selection of mechanical seals and supply systems for the whole plant and supplied more than 95 % of the components in use.

In Great Britain, a shortage in natural gas supply has severe consequences: Since the country switched from coal-fired to gas-fired power stations, a gas supply shortage makes households and industrial consumers not only vulnerable to failing heating and gas stoves, but also to power outages. Companies along the value and transportation chain of natural gas are therefore especially dependent on reliable equipment.

Things get hot in rotary kilns, very hot in fact. In the production of cement, for example, the thermometer measures more than 1,000 degrees Celsius. Sealing systems from EagleBurgmann, a company of the Freudenberg Group and EKK, make sustainable contributions to environmental protection, energy efficiency and process reliability under these "fiery" high-temperature conditions.

Our modern civilization is quite literally built upon cement. Today, building materials made from cement are used in buildings, roads, bridges, dams etc. Cement production is a heat-intensive process and causes thermal expansion in duct systems. To compensate this, Indian cement producer Ramco Cement needed fabric expansion joints with a diameter of several meters for two of their plants. On the basis of a close collaboration, EagleBurgmann was able to design components that increase the efficiency of the plant in the long run.

Frequent starts and stops are a severe test for gas-lubricated compressor seals. Installed in an Argentinean combined cycle power plant is an EagleBurgmann supply system that provides a continuous gas flow rate for the seals and adapts it to changing conditions. Since then, the operational reliability of the compressors has increased significantly.

Seals are a risk factor in the production of liquid crystals. If there is even the slightest contamination of the liquid crystals, this will later affect the image quality of the display. Read on to see which sealing solution Merck KGaA uses in paddle dryers for the production of liquid crystals.