Thermoflon 6230

Thermoflon 6230

Thermoflon 6230

Features

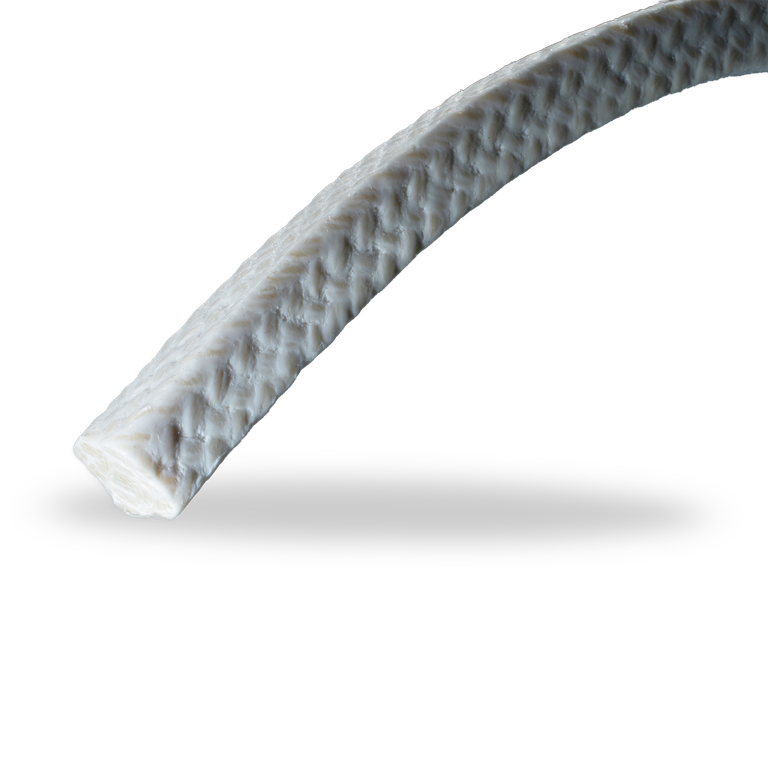

Thermoflon 6230 is a diagonally braided packing made from 100% genuine GFO (graphiteincorporated PTFE yarn). With its universal structure, the packing is used in almost every branch of industry.

Advantages

- Treats shafts gently

- High cross-sectional stability

- Highly flexible

- Outstanding functional efficiency

- Very good emergency running properties

- Very high thermal conductivity

- No embrittlement

- Does not age

- Long service life

Recommended applications

Industries

- Process industry

- Oil and gas industry

- Petrochemical industry

- Chemical industry

- Pharmaceutical industry

- Power plant technology

- Pulp and paper industry

- Water and waste water technology

- Mining industry

- Building services industry

- Food and beverage industry

- Shipbuilding

- Sugar industry

- Metal production and processing

- Pumps

- Agitators

- Mixers

- Kneaders

Variants

6230/AK (braided in AK-profile)

Notes

For sealing hot water pumps, the required leakage must always emerge in liquid form in order to lubricate the packing. The compression packing will have to be cooled via a lantern ring or a jacket, gland or shaft cooling system if the heat radiation via the stuffing box housing is not sufficient.

Forms of supply

- Sold by length, blank cuts, precompressed rings with straight or slanted cut

- Box contents

up to 6,35 mm: 1 kg

7 - 10 mm: 2 kg

11 - 13 mm: 3 kg

14 - 24 mm: 5 kg

from 25 mm: 10 kg

Similar products

Araflon 6426

Araflon 6426 is a packing made from high quality, smooth, synthetic and partly pre-impregnated continuous aramid fibers (Kevlar) with multiple applications of PTFE impregnating agent and lubricant additive. The aramid fibers are diagonally braided. This is a high quality and high strength packing. It is used, in particular, in the chemical, petrochemical, waste water and paper industries.

Buraflex HT 2000/HT

Buraflex HT 2000/HT is a packing made from expanded graphite combined with Nomex yarn corners. The Buraflex HT is a special packing for applications with high temperatures and peripheral speeds.

Buraflon 5846

Buraflon 5846 is a diagonally braided, silicone oil-free ramie fiber packing with a light-colored special PTFE impregnating agent based on paraffin wax and oil. This special combination will prevent product contamination. The packing is preferred for use in marine applications, the brewing and drinks industry and the pharmaceutical industry. It is a flexible, maintenance-friendly and easy to adjust packing that is gentle on shaft surfaces.