EagleBurgmann international

Ireland

UK

Ireland

UK

Ireland

UK

Ireland

UK

Ireland

UK

Ireland

UK

EagleBurgmann WORLDWIDE

With around 250 locations and 90 serve centers, we are represented in the most important economic regions of the world. The advantages are clear: short paths to our customers, fast response times and a shared language.

Rubber expansion joints

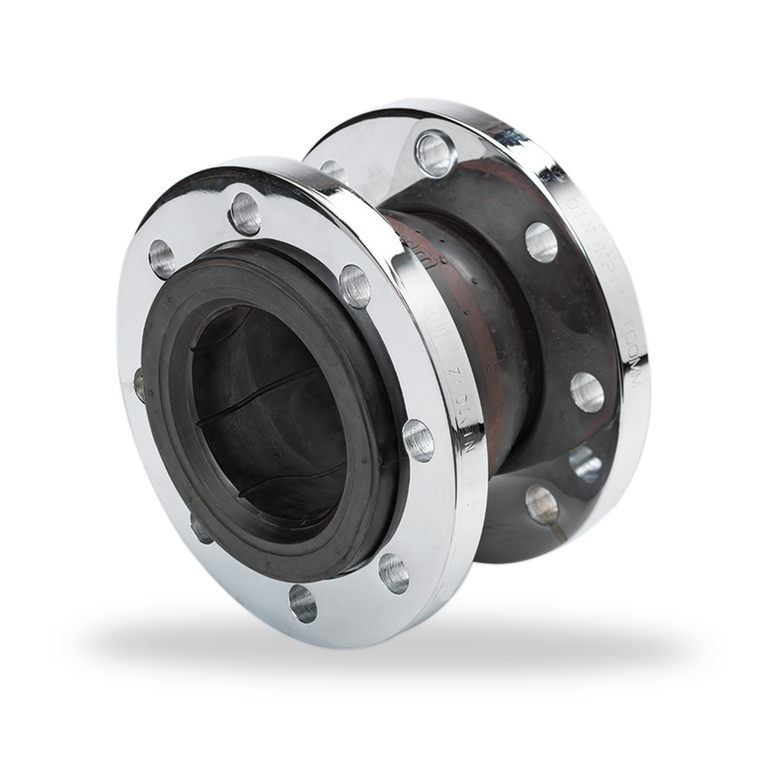

Rubber Hose Type

Rubber Hose Type

expansion joints

Rubber hose type

| Item | Description |

| 1 | Rubber bellows |

| 2 | Flanges |

| 3 | Reinforcement ring |

Rubber Hose Type

expansion joints

Features

- Transportation or piping systems that carry fluids, slurries or gasses under pressure or vacuum at varying temperatures.

- Reduction of vibration

- Dampen sound transmission

Advantages

- Easy installation

- Flanges are not in contact with medium, which enables lower grade material

- Galvanic surfaces/ coatings possible

- Gaskets can be eliminated

- Manual production

- Special measures (length, diameter, flanges) → custom made

Operating range

Diameter: DN 25 ... DN 2,000 mm (1” ... 80”)

Pressure: as per request

Temperature: up to 180 °C (356 °F)

Movements: vibrations

Pressure: as per request

Temperature: up to 180 °C (356 °F)

Movements: vibrations

Materials

- Bellows: Various elastomers such as EPDM, EPDM Food Grade, Neoprene, Nitrile, Hypalon, Butyl, Viton.

- Flanges: carbon steel and stainless steel.

-

Other materials are available on request.

Standards and approvals

NDT and documentation: Can be provided per customer request e.g. Material Certificates and NDT test reports.

Recommended applications

- Pumps

- Chemical transport lines

- Water transport

- Pulp and paper industry

Similar products

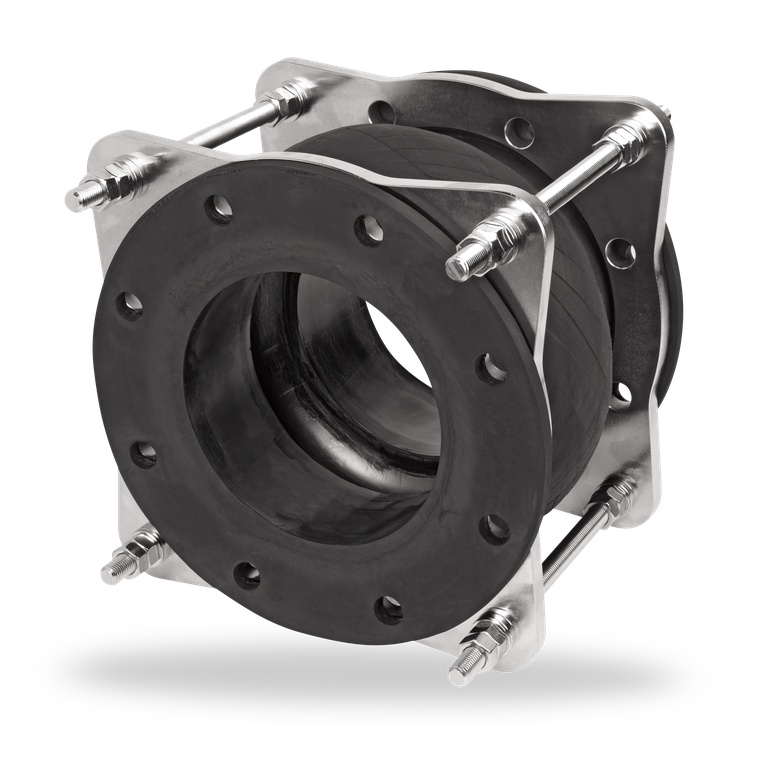

D Type expansion joints

- Transportation or piping systems that carry fluids, slurries or gasses under pressure or vacuum at varying temperatures

- Reduction of vibration

- Dampen sound transmission

- Compensate movements due thermal changes, misalignments caused by wear, load stresses, settling of supporting foundations

- Molding production with long radius arch

- Standard measures (length)

DFS Type expansion joints

- Transportation or piping systems that carry fluids, slurries or gasses under pressure or vacuum at varying temperatures

- Reduction of vibration

- Dampen sound transmission

- Compensate movements due thermal changes, misalignments caused by wear, load stresses, settling of supporting foundations

- Molding and manual production.

- Standard measures (length)

Contact

Inquire about individual solutions

We develop and produce customer-specific special and individual solutions for every application.