Injectable packings for chest agitators

Numerous chest agitators are implemented in the paper industry. They are normally sealed with conventional compression packings which are additionally flushed. Often, this kind of sealing cannot prevent excessive leakage and therefore a loss of product. The retrofit of a mechanical seal in very old machines would result in economically unreasonable costs. In these cases, EagleBurgmann injectable packings have proven their worth in practice. Loss of media is therefore history; the area surrounding the machine stays clean, and maintenance work becomes easier.

Product: Burajet SCA; medium: water and pulp fibers, temperature: t = 20 °C … 25 °C (68 °F … 77 °F), pressure: p = 4 bar (58 PSI).

Mechnical seals in several pumps of paper machines

At Stora Enso Kvarnsveden, Sweden, several pumps of the paper machines are sealed with EagleBurgmann MA251. Medium: pulp with a solids content up to 1.5 %.

Operating conditions: p = 2 bar (29 PSI), t = 30 °C ... 40 °C (86 °F ... 104 °F), n = 1,490 min-1.

Flow control unit for all double seals

The EagleBurgmann FLC200 flow control unit is used for all dual seals of the Stora Enso Skutskär paper mill in Sweden in order to adjust the volume of supplied water as needed. Safe operation of the seals is thus ensured.

Operating conditions: p = 25 bar (363 PSI), t = 85 °C (185 °F).

Eccentric screw pumps with cartridge seals

At Iggesund Paperboard, Workington, UK, eccentric screw pumps with MG1S50 type cartridge seals are operating reliably in the coating plant.

Medium: Coating color, p3 = 4 bar (58 PSI), t3 = 40 °C (104 °F), n = 850 min-1.

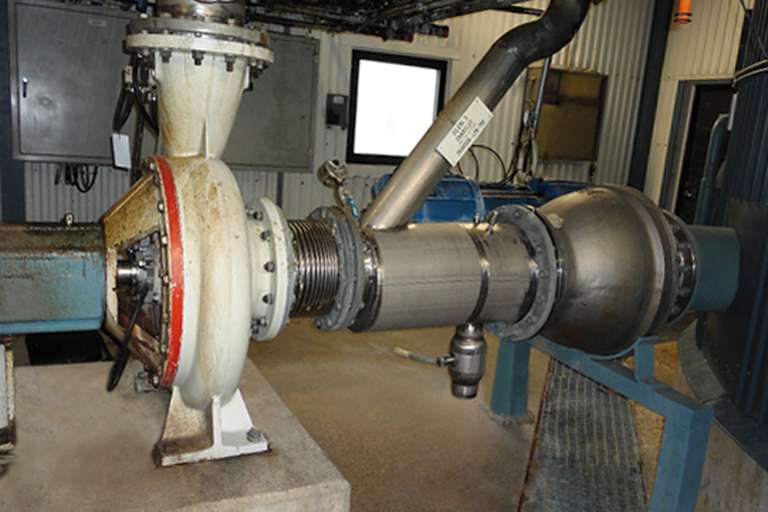

Reliable sealed feed pump since 1988

At the UPM Pietarsaari paper mill in Finland, a feed pump for pressure screens is sealed by an EagleBurgmann LP-Q-SA2-DZXX70/160. Installed since 1988, overhauled in 2000, it operates reliably up to today.

Operating conditions: p = 2 ... 3 bar (29 ... 44 PSI), t = 60 °C ... 70 °C (140 °F ... 158 °F), n = 750 min-1.

Fabric expansion joint for an air duct system

A Yankee Flex 350 type fabric expansion joint with an outer layer of Alusil is installed in an air duct system at the paper mill of Procter & Gamble Paper in Oxnard, USA. The expansion joint is reliably tight and flexible.

Operating conditions: t = 343 °C (649 °F), rate of flow = 15 m/s (49 ft/s).

Cartridge seal for sealing white water

An EagleBurgmann MA291 type mechanical seal operates at the Hakuetsu Paper in Nayo, Japan andseals the white water of the paper machine.

Operating conditions: p = 2 bar (29 PSI), t = 100 °C (212 °F), n = 1,470 min-1.

Single cartridge seal for pulp pump

An EagleBurgmann MA291/60 type single cartridge seal is installed in a Sulzer APP pump at an Indonesian paper mill. The medium to be sealed is pulp with a solids content of 5.5 %.

Operating conditions: p = 4 bar (58 PSI), t = 60 °C (140 °F), n = 1,430 min-1.

Cartridge seal Cartex-DN for black liquor

In the pulp production at Stora Enso Skutskär in Sweden, a Sulzer APP Ahlstar pulp pump transports the pulp with black liquor to the washing and bleaching processes. The pump is equipped with an EagleBurgmann Cartex-DN with a connected BestFlow pressure regulating valve for the optimum supply of buffer water to the seal.

Operating conditions: p = max. 4.5 bar (65.3 PSI), t = 66 °C (151 °F), n = 956 min-1.

Download the PDF for the full story

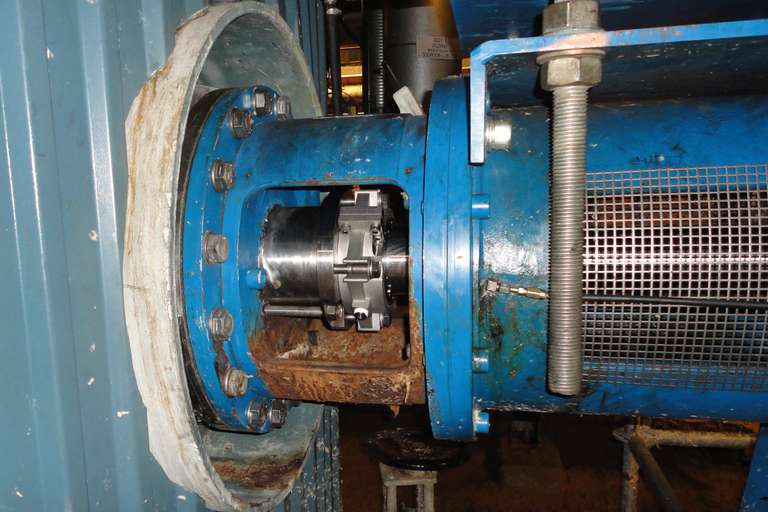

Fully split mechanical seal for mixer and chest agitator

After retrofitting at Stora Enso in Sweden, two fully split EagleBurgmann Splitex type mechanical seals operate successfully in a mixer with bottom entry and a chest agitator with side entry. Here, pulp having a solids content of over 11 % is sealed.

Operating conditions: p = 10.3 bar (149 PSI), t = 180 °C (356 °F), n = 15 min-1.

Download the PDF for the full story.

Elastomer bellows seals in several pumps

MG1S14 type elastomer bellows seals are supplied as standard cartridge and also fit in ABS Scanpump pumps and Sulzer APP pumps. Alone more than 40 seals are being applied successfully at the Stora Enso Kvarnsveden/Sweden paper mill.

Operating conditions: p = 8 ... max. 10 bar (116 ... 145 PSI max.), t = 60 °C (140 °F), n = 1,490 min-1.

Download the PDF for the full story.